Panel cutting and processing

Contract work – achieving more together

Our main areas of expertise are primarily in the following areas:

- Panel cutting and processing

- Real wood processing (solid and veneered)

- 5-axis CNC machining

- Surface treatment

Our machine park

Edition 25

Machining dimensions (L x W x H)

5600 mm x 2100 mm x 100 mm

HOMAG Säge SAWTEC B-300

profiline

Machining dimensions (L x W x H)

5600 mm x 5600 mm x 90 mm

Machining dimensions (L x W x H)

4000 mm x 2000 mm x 60 mm

BMG Venture 316L

Machining dimensions (L x W x H)

4375 mm x 1550 mm x 150 mm

HOMAG Group Breitband

OPTIMAT

1350 mm width

With supply and exhaust air system to achieve optimal results even in the high-gloss area.

MPH 410/25/07

Max. dimension

2500 mm x 1400 mm

Decorative chipboard

Plain colors or wood decor

We offer a suitable ABS edging for every decor

The chipboard consists of differently sized, glued wood chips that are pressed together in several layers. The outer layers are almost always made of finer chip material. The chipboard is coated on both sides with melamine resin-impregnated decorative paper.

Available colors and decors

Further information on panel dimensions and prices can be found in our price list.

Composite elements

Composite elements are carrier plates which are covered with HPL on both sides.

With HPL panels, several layers of paper are soaked in melamine resin. After curing, the resin creates a thermosetting plastic.

Available colors and decors

Further information on panel dimensions and prices can be found in our price list.

Raw panels

Our range in different designs.

Chipboard raw

Rear panel white on one side

MDF raw

Primer film

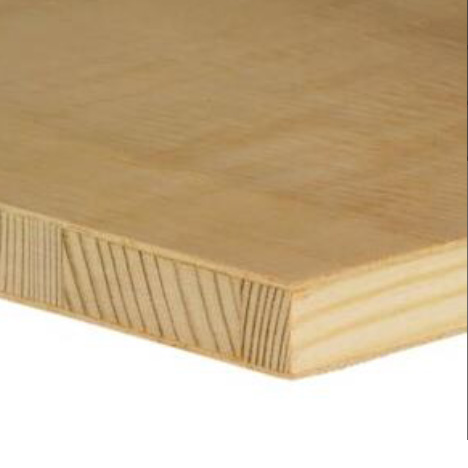

Blockboard MDF_Deck

Solid wood panels

Three-ply and glued wood panels

Edge-glued oak board

Three-layer spruce board

Veneer panels

Multiplex birch

Birkoplex fir